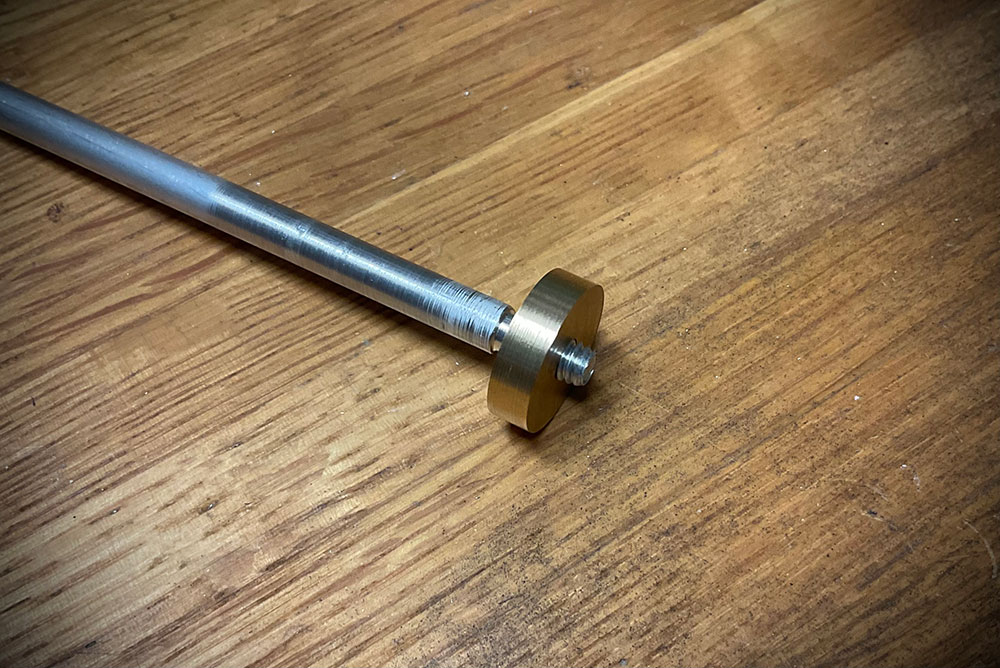

A two week Easter break is so far proving fruitful with the stock escutcheon nut recreation underway. I was going to start with some 5mm brass sheet but decided on using 20mm round bar stock after the sheet was delayed in shipping and I could source the round bar locally. I think it’ll be a better option anyway being able to lathe turn much of it.

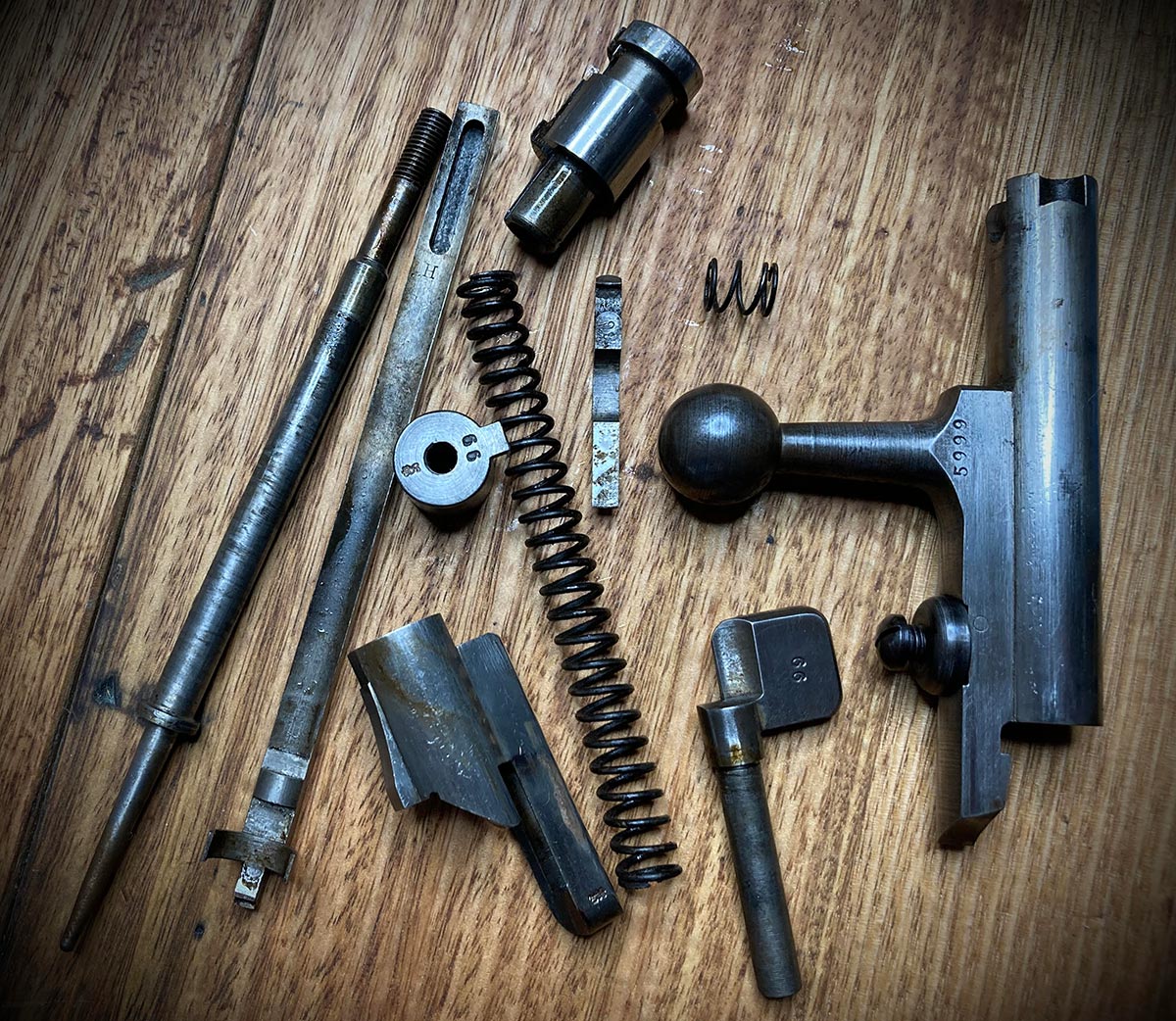

Considering the nut is 19mm in its maximum dimensions, this should work quite well. That said; I have already run into a bit of an issue and while not unexpected, it’ll cause a slight delay. Unfortunately while the screw threads are still present, they are very worn after 130 years. I did get the nut blank to the point of being threaded.

I’ve decided that the screw’s threads will need to be cleaned up as well and as such I’ve ordered the appropriate die to do it. Once that arrives, I should be able to finish up the threading component and move onto the final shaping to fit the stock recess.